Steeline’s On-Site Manufacturing: Cutting Costs for Colorbond Shed Builders

Shed builders who adopt on-site fabrication for Colorbond sheds, like Steeline, gain significant advantages including streamlined production, reduced lead times, and precise customization. This approach eliminates the delays of transporting pre…….

Shed builders who adopt on-site fabrication for Colorbond sheds, like Steeline, gain significant advantages including streamlined production, reduced lead times, and precise customization. This approach eliminates the delays of transporting prefabricated parts from remote facilities, mitigates transit damage risks, and ensures high-quality component assembly on-site. The direct fabrication process minimizes handling stages, cutting down errors, waste, and project timelines, enhancing overall efficiency. Clients benefit from swifter shed erection and lower costs due to these efficiencies, and the method also promotes sustainability by lessening transportation and storage environmental impacts. By prioritizing quality craftsmanship with on-site manufacturing, shed builders offer durable Colorbond sheds tailored to specific client needs promptly. Choosing a shed builder with Steeline's local manufacturing capabilities for your Colorbond shed project is a cost-effective and timely decision that aligns with budgetary constraints and completion goals.

Steeline’s innovative approach to on-site manufacturing is revolutionizing the way shed builders and those opting for Colorbond sheds operate, offering unparalleled cost savings. This article delves into how this localized production method not only maximizes efficiency and economy but also streamlines the creation of Colorbond sheds, directly benefiting your next project’s bottom line. Through a detailed case study, we’ll explore the tangible financial advantages shed builders have realized by leveraging Steeline’s on-demand manufacturing solutions for custom sheds.

- Maximizing Efficiency and Economy: Steeline's On-Site Manufacturing for Shed Builders

- Streamlining Production: How Colorbond Sheds Benefit from On-Site Fabrication

- Cost-Saving Advantages: The Impact of Localized Manufacturing on Your Next Project

- Case Study: Real Savings Achieved with Steeline's On-Demand Production for Custom Sheds

Maximizing Efficiency and Economy: Steeline's On-Site Manufacturing for Shed Builders

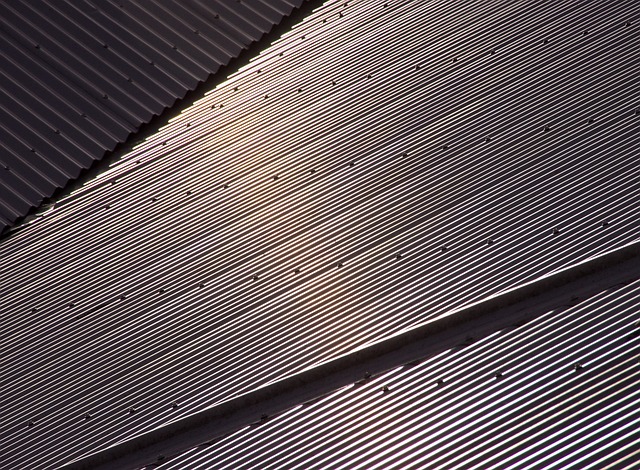

Steeline’s on-site manufacturing process is a game-changer for shed builders seeking to maximize efficiency and economy in their projects. By bringing the production facilities directly to the construction site, Steeline minimizes transportation costs and time delays associated with traditional manufacturing and delivery methods. This approach not only streamlines operations but also reduces the carbon footprint typically involved in constructing colorbond sheds. The immediate on-site fabrication allows for a more precise fit and finish, as materials are cut and formed where they will ultimately be installed. This ensures that shed builders can provide their clients with high-quality, customized colorbond sheds without the added expenses of material handling and long-distance shipping. Moreover, the on-site system enables builders to maintain a consistent supply chain, leading to faster project turnaround times and more predictable budgeting for both the builder and the customer. The result is a cost-effective solution that benefits all parties involved in the construction of colorbond sheds. Shed builders who adopt Steeline’s on-site manufacturing can differentiate themselves in the market, offering superior value and service to their clients, while also positioning themselves as leaders in innovation and sustainability within the industry.

Streamlining Production: How Colorbond Sheds Benefit from On-Site Fabrication

When it comes to constructing Colorbond sheds, on-site fabrication presents a multitude of advantages for shed builders and clients alike. This process involves manufacturing the steel components at or near the construction site, which not only streamlines production but also significantly reduces lead times. By leveraging on-site manufacturing, shed builders can customize Colorbond sheds to precise specifications without the delays inherent in transporting pre-made parts from distant facilities. This approach minimizes the risk of damage during transit, ensuring that each component arrives in optimal condition, ready for assembly. The directness of on-site fabrication means fewer handling stages and a reduction in the potential for errors or material wastage. As a result, clients benefit from a swift turnaround, with their Colorbond sheds being erected with greater efficiency and accuracy. This not only lowers costs associated with delays but also reduces the environmental impact typically linked to transportation and storage of materials. Thus, on-site manufacturing is a cost-effective solution that enhances the quality and timeliness of Colorbond shed construction. Shed builders who adopt this method demonstrate a commitment to excellence, providing clients with sheds that are not only durable but also tailored to their unique needs with minimal wait time.

Cost-Saving Advantages: The Impact of Localized Manufacturing on Your Next Project

When embarking on a new construction project, such as constructing a shed or a similar structure, partnering with a shed builder like Steeline who offers on-site manufacturing can yield significant cost savings. This localized approach to production eliminates the need for long-distance transportation of materials, which traditionally involves hefty shipping costs and potential delays. By fabricating your Colorbond sheds at a facility close to the project site, Steeline minimizes logistical expenses, directly benefiting you. The proximity of the manufacturing plant ensures that materials are delivered promptly, reducing labor costs associated with waiting for deliveries or managing job site logistics. Furthermore, on-site manufacturing allows for greater efficiency and precision in the production process, as materials can be cut and treated to specification immediately before installation. This level of control and immediacy not only speeds up project timelines but also reduces waste and the likelihood of returns due to damage during transit, further contributing to cost savings. Choosing a shed builder with an on-site manufacturing capability, like Steeline, for your Colorbond sheds ensures that you are making a cost-effective decision that supports both your budget and schedule.

Case Study: Real Savings Achieved with Steeline's On-Demand Production for Custom Sheds

In conclusion, Steeline’s innovative on-site manufacturing approach not only streamlines production processes but also significantly lowers costs for customers, particularly shed builders and those investing in Colorbond sheds. The efficiency gained through localized manufacturing translates directly into tangible savings on projects. A recent case study highlights the substantial financial benefits achieved by leveraging Steeline’s on-demand production capabilities for custom sheds, underscoring the value this method brings to the table. For shed builders and buyers alike, embracing on-site fabrication is a strategic move towards cost-effective and timely project completion.