On-Site Craftsmanship: The Shed Builder’s Art of Creating Colorbond Shed Solutions

Local shed builders specialize in crafting bespoke Colorbond sheds that combine functionality with design, tailored to meet various regional needs. These sheds are made from durable and weather-resistant Colorbond steel, ensuring they are both …….

Local shed builders specialize in crafting bespoke Colorbond sheds that combine functionality with design, tailored to meet various regional needs. These sheds are made from durable and weather-resistant Colorbond steel, ensuring they are both long-lasting and visually appealing. The shed builders' expertise with Colorbond materials ensures each structure is custom-built for optimal performance, seamlessly integrating with the local landscape to provide robust protection against environmental elements while maintaining a sharp appearance. On-site manufacturing by these skilled professionals enhances efficiency and quality, with the ability to fabricate purlins and roofing components directly at the job site, leading to a precise fit and minimal waste. This on-site approach not only streamlines the building process but also reduces transportation and storage costs, resulting in swift, cost-effective, and high-quality Colorbond shed construction that satisfies both residential and commercial needs. Colorbond sheds are a significant innovation, favored for their durability, aesthetic versatility, and thermal efficiency, making them an ideal choice for sustainable and low-maintenance building solutions. They offer a harmonious blend of design, practicality, and longevity, setting a high standard in the construction industry as a testament to modern craftsmanship and innovation.

Discover the intricate artistry and technical prowess behind shed construction as we delve into the world of local shed builders specializing in Colorbond sheds. These skilled craftsmen harness advanced on-site manufacturing techniques to produce robust and aesthetically pleasing structures. From the foundational purlins to the protective roofing, each component is expertly crafted, showcasing the versatility of Colorbond materials. Join us as we explore the craftsmanship and innovation at the heart of this thriving industry.

- Exploring the Craftsmanship of Local Shed Builders and Their Role in Constructing Colorbond Sheds

- The Manufacturing Process: From Purlins to Roofing – A Closer Look at On-Site Production Techniques

- The Versatility of Colorbond Materials in On-Site Manufactured Structures

Exploring the Craftsmanship of Local Shed Builders and Their Role in Constructing Colorbond Sheds

Local shed builders are the artisans behind some of the most robust and durable Colorbond sheds gracing homes across various regions. Their expertise lies in their ability to craft structures that blend functionality with aesthetic appeal, utilizing high-quality materials like those found in Colorbond sheds. These builders understand the importance of tailoring each shed to meet the specific needs and environmental conditions of the area, ensuring a perfect fit for any backyard or commercial property. The use of Colorbond steel, known for its longevity and weather resistance, is a testament to their commitment to quality and customer satisfaction. The process begins with meticulous planning and design, followed by precise cutting and assembly on-site, which allows for a seamless integration with the surrounding landscape while offering protection against the elements. The local shed builders’ skill in working with Colorbond materials not only contributes to the longevity of the sheds but also to their visual appeal, making them a valued addition to any property. Their role extends beyond construction; it’s about creating spaces that are as practical as they are long-lasting, providing homeowners and businesses with versatile solutions for storage, workshop space, or even outdoor living areas. The collaboration between these skilled craftsmen and the innovative design of Colorbond sheds results in structures that stand the test of time, both structurally and aesthetically, ensuring that each shed is a fine example of local craftsmanship and modern building techniques.

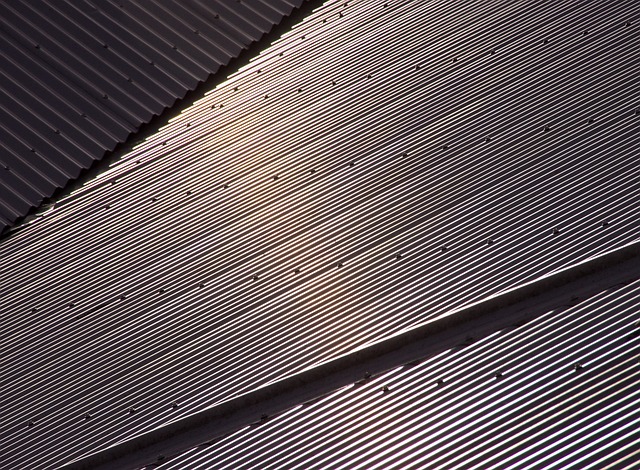

The Manufacturing Process: From Purlins to Roofing – A Closer Look at On-Site Production Techniques

In the realm of construction, particularly in the erection of sheds and other structures, on-site manufacturing plays a pivotal role in efficiency and quality. Skilled shed builders often utilize advanced techniques to produce purlins and roofing components directly at the site of construction. This approach not only streamlines the building process but also ensures that the colorbond sheds are tailored to the specific requirements of the project, resulting in a precise fit and reduced waste. The manufacturing process begins with the cutting and shaping of raw materials into purlins, which serve as the skeletal support for the structure’s roof. These purlins are crafted on-site using high-grade steel, ensuring they meet stringent structural integrity standards. Subsequently, the sheets of Colorbond® steel, known for their durability and range of aesthetically pleasing colors, are cut and folded into roofing panels. The on-site production of these panels allows for immediate application to the purlins, creating a seamless transition from support to cover. This method leverages state-of-the-art machinery and the expertise of seasoned shed builders, who work in tandem to deliver robust and weather-resistant roofing systems. The on-site manufacturing process is not only cost-effective but also minimizes the time required for material transportation and storage, which can often be logistical challenges in remote or constrained locations. As a result, the integration of on-site production techniques for purlins and Colorbond® roofing ensures a swift and high-quality completion of colorbond sheds, contributing to the overall efficiency and satisfaction of the construction project.

The Versatility of Colorbond Materials in On-Site Manufactured Structures

In the realm of on-site manufacturing, the versatility of Colorbond materials stands out, particularly in the construction of sheds and other steel structures. Shed builders across Australia have long relied on Colorbond for its durability and aesthetic appeal. This steel alloy, renowned for its resistance to harsh climates, is a favored choice for both residential and commercial applications due to its wide range of colors that mimic the look of traditional materials like timber and zinc, while offering greater longevity and less maintenance. The unique coating on Colorbond sheds ensures that they are resistant to chipping, fading, and scratching, providing a consistent visual appeal over time. Furthermore, the material’s adaptability allows for intricate designs and custom configurations, making it an ideal solution for a variety of projects, from small garden sheds to large agricultural buildings. The thermal properties of Colorbond materials also contribute to energy efficiency, enhancing the overall performance of the structures they form. This makes them not only a visually pleasing option but also a sustainable and cost-effective one for shed builders and their clients. Colorbond sheds are a testament to the ingenuity of on-site manufacturing processes, offering a blend of form, function, and resilience that is hard to match with other building materials.

In conclusion, the intricate craftsmanship of local shed builders stands as a testament to their skill and dedication in constructing robust Colorbond sheds. The manufacturing process of these structures, from purlins to roofing, is a fine example of on-site production techniques that highlight efficiency and versatility. The use of Colorbond materials showcases the adaptability and durability inherent in these sheds, making them suitable for a wide array of applications. By leveraging local expertise and innovative manufacturing methods, shed builders are able to deliver products that not only meet but exceed expectations, ensuring homeowners and businesses alike can find a perfect fit for their storage or workspace needs.